Revolutionary Biological Treatment Technology

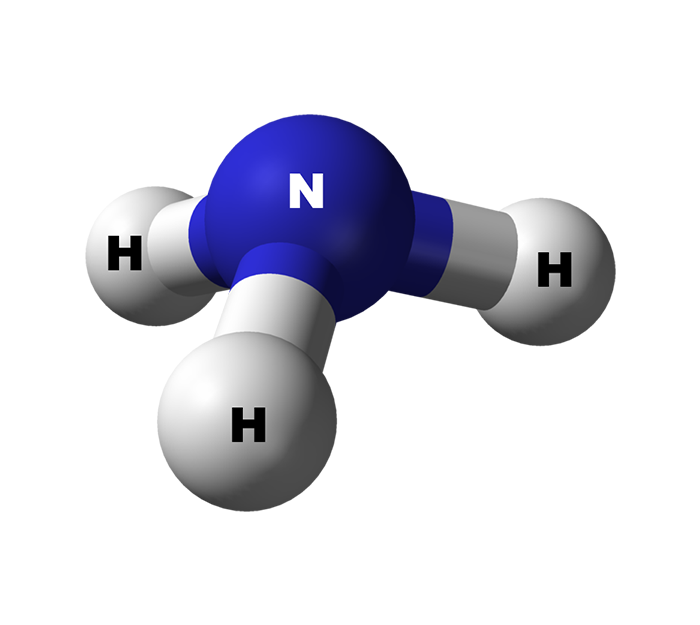

Ammonia Nitrification

Ammonia is a major concern for most of the effluent treatment plants specially crude oil ETP and Sewage treatment plants. The ammonia concentration at inlet affects biological processes hence COD reduction. If ammonia is discharged from a treatment plant it can harm aquatic life.

The process of ammonia reduction is known as nitrification. This process specifically includes conversion of ammonia to nitrate.

Ammonia (NH3) > Nitrite (NO2-) > Nitrate (NO3-)

- One molecule of NH4+ uses 1.5 molecules of O2 to change into Nitrite

NH4 + 1.502 > NO2- + H20 + 2H+

- Nitrite converts into Nitrate using 0.5 molecule of O2

N02- + 0.502 > NO3-

- So the nitrification reaction taking place in the aeration bioreactor is:

NH4 + 2O2 > NO3- + H20 + 2H+

While most of the aerobic systems are unable to treat ammonia in the effluent and it affects their performance, BPC ACT system is not only immune to high ammonia (50-500 ppm) concentration but also can treat ammonia without any extra infrastructure . The unique quality of bacterial Isolation of ACT enables stable biological process as well as stable quality of treated effluent irrespective of ammonia in effluent. The specified bacteria strain uses the nitrified ammonia as energy source in the form of nitrate and nitrite, thus it saves the extra chemical cost for nitrogen addition in the aeration system.

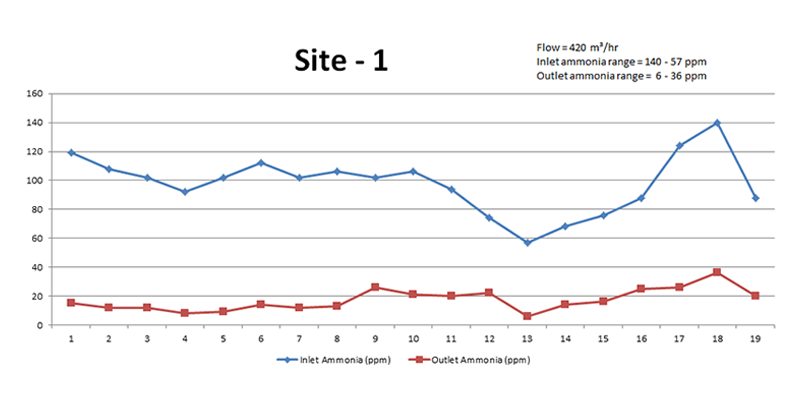

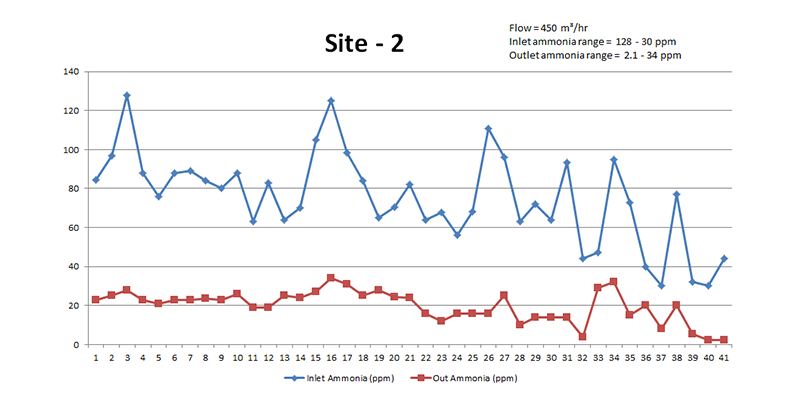

BPC has active sites where the inlet ammonia varies from 50- 500 ppm at inlet and the outlet of the plant is not exceeding the desired result values. Two of such sites are given below :

Process Efficiency

Significant deduction in OPEX resulted through advanced automation.

Less Sludge generation when compared to conventional technologies.

Better resiliency & stable output performance against inlet shocks.

Why Choose

ACT Technology

Automated Chemostat Treatment (ACT) starts with selecting the most efficient bacteria cocktail from the process effluent on BPC’s labs, once this process specific bacteria cocktail is isolated and bacteria cocktail is prepared, the bacteria in delivered to the site as a one time starter. In the bioreactor itself the cells are maintained at a very low concentration inside the bio reactor (MLSS value of around 100-400 ppm dependence on the organic load in the system.

The bacteria concentration is distributed throughout the bio reactor and they act as single cell treatment units as no aggregates are formed; this ensures that the biological oxidation process is highly effective when compared with the concentration that has to be maintained within the bio reactor.

BPC’s ACT is a one flow system as there is no need of recalculating sludge to maintain the required bacteria population in the bio reactor, the rate of growth of the bacteria culture within the bio reactor is always maintained at a rate equal to or higher than the rate at which bacteria culture is being washed away with the out flowing effluent. The HRT for ACT is equal to the sludge retention time, as the bacteria age in the ACT bioreactor is low, the bacteria culture is maintained in its logarithmic growth phase, and this young bacteria population ensures higher bacteria activity and ensures that the process is highly efficient in consuming organic contaminations.

Complete automation and stability are two of the primary advantages of the BPC-ACT system. Each installation is monitored by a series of online sensors with real-time reaction capabilities. Errors in the system are immediately detected by ACT and dealt with through automatic troubleshooting. Control systems notify operations personnel via SMS and email. This ensures that BPC’s ACT is able to respond to any changes in the effluent parameters in real time.

The BPC-ACT process transforms water treatment into a more efficient, economical, and ecologically-friendly process using its patented technologies. The system can be applied to a wide range of sites.

Unmatched Stability

ACT Provides Unmatched Stability in face of upsets of organic load and contaminations in the system. This stability is due to a unique control system that automates the complete process of biological treatment (Aeration) which is available only with ACT.

Closed loop Automation

All system parameters are measured online and there is no requirement for laboratory based tests that take 2-3 days to give results. The system runs completely automatically without the need of constant human intervention, handling upsets as they happen.

Broad MLSS Spectrum

ACT is the only system in the world that can operate at a wide variety of MLSS (lowest 300ppm) and F/M ratio (varying between 2 to 20), which means ACT can manage higher inlet fluctuations (both high and low) in organic load than any other system.

Better Upset handling

Conventional systems are not able to perform for 2-3 weeks following an upset resulting in effluent which has parameters over the design limits. ACT is able to avoid most upsets and if an upset occurs, the recovery time is 2-3 days.

Better RO Downstream stability

With an RO system downstream the stability that ACT offers is very important. The RO uptime (operational) is maximized, with no need for dilution of RO make up stream due to ETP non performance during an upset and the recovery.

Better Effluent treatment

Investment in treating effluent that is above specifications is much higher at the RO (chemical precipitation and Ultra Filtration), when it is compared with the investment it takes in the ETP to ensure that effluent is treated properly.

WORKING OF

ACT Technology

- A bacteria batch is isolated from the effluent.

- This bacteria culture is maintained in an Auto-Starter Basin (batch reactor which is 10% of the main bioreactors volume) near the bioreactor in case the system needs to be shutdown (e.g. for maintenance), the culture is always ready to repopulate the bioreactor, and the bacteria culture is the proprietary information of the client (in this case IOCL Panipat Refinery)

- A control system monitors parameters like TOC(Total Organic Carbon), TN(Total Nitrogen), TP(Total Phosphorus), pH, DO(Dissolved Oxygen), OUR(Oxygen Uptake Rate), and based on these parameters runs the system automatically, ensuring smooth operations and instantaneous reaction to inlet parameters.

ACT PROJECTS IN

INDIA

- IOCL PTA ETP - Panipat, Haryana

- OPAL Petrochemical Complex Installation (Operational since 2016- EIL managed Tender) - Dahej, Gujarat

- BPCL Refinery, ETP under Integrated Refinery Extension project - Kochi, Kerala

- Naroda Enviro Projects Limited CETP - Naroda, Gujarat

- HMEL Refinery - Bhatinda, Punjab

Testimonials

What Our Client’s Say

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

contact us

Book your free consultation

Got any questions regarding our technology ?

Let us know, we will be glad to assist!!!