Patented Act Sequential Bioreactor Process

Aerobic Bioremediation with

ACT Sequential Mode System

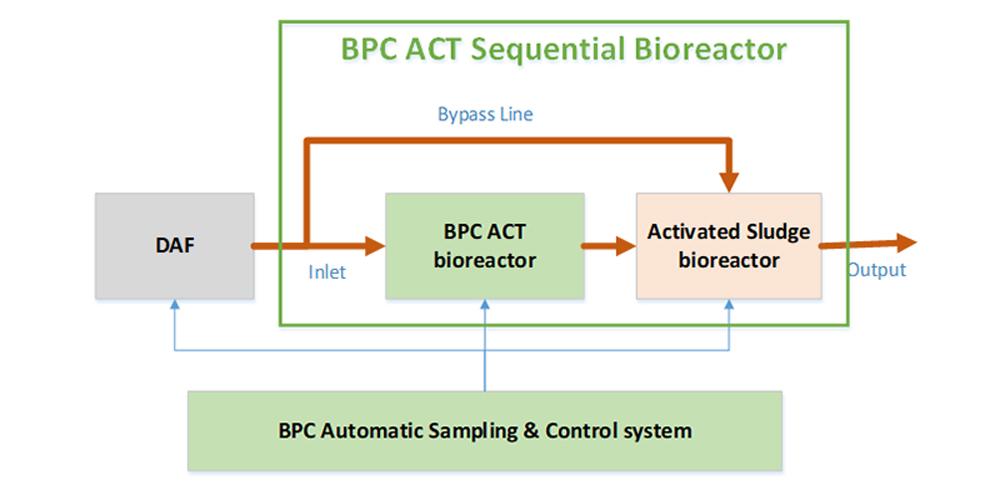

Getting High & Sustainable Quality treatment is the most challenging objective to achieve which is made possible by our patented process named ACT Sequential mode Bioremediation System. This process utilizes the same retention time (reactor volume) but splitting it in two sequential reactors.

The first reactor is always an ACT reactor (low biomass, robust bioremediation with young bacteria), the second reactor can be one of the conventional HIGH Biomass reactor (Activated sludge, SBR, MBR)

This patented setup takes “the best of both worlds” and provides complete process stability in an elegant way (avoiding the need for equalization and “Off spec” volumes) and also reducing chemical usage in pre and post treatment.

Why is ACT sequential mode the correct choice for any Industrial wastewater treatment plant (ETP)?

Absorb

Inlet Fluctuation

Guarantee sustainable performance, this is extremely important in case of CETP that treats a large variety of industrial/municipal streams.

.01

Sulfide

Oxidation

Treated in the ACT and without H2O2 (in some cases, like refineries, this is a significant OPEX savings)

.05

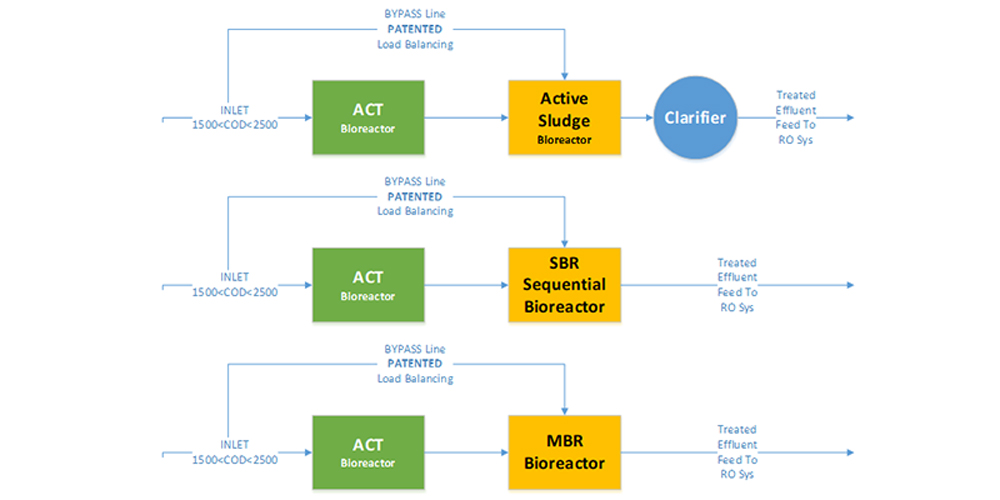

All the optional ACT sequential bioremediation system presented above provides high value to any industrial WWTP. (Improved Quality, Performance Stability, OPEX Savings and ease of use). Yet, each optional setup has unique value that will best fits a specific application

Optimal settings for various WWT Applications:

- ACT + Activated Sludge can be optimal for a case that the plant is already available and we need to deliver an ACT UPGRADE (we normally convert one channel to ACT or transform an equalizing tank into an ACT, and keep the existing activated sludge as second reactor)

- ACT + SBR can be optimal in plants where size is of limit and there is no special demand for extra high quality (like when COD

- ACT + MBR is optimal for sites that wish to reuse the treated effluent (or send it to a RO System)

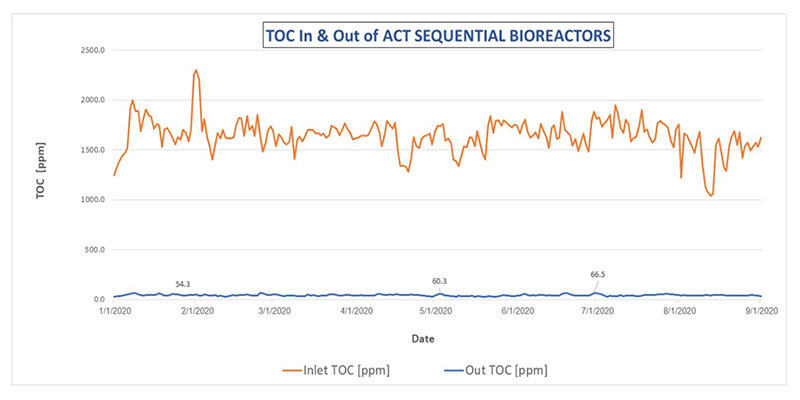

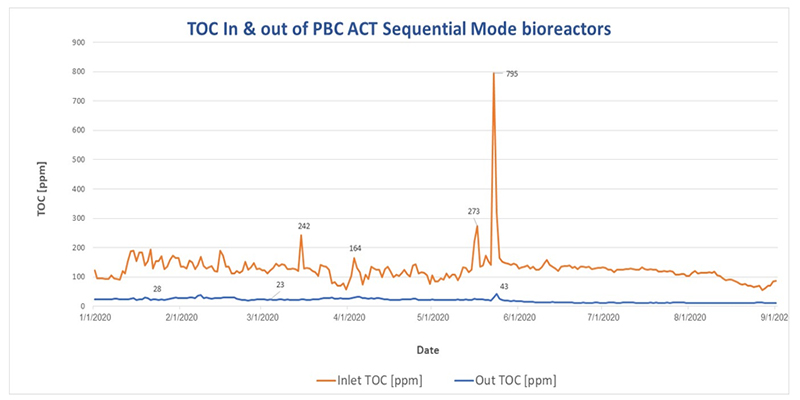

The following are the actual results from two different refineries (a crude oil refinery with flow rate of 500 m³/hour, and a PTA refinery with flow rate of 230 m³/hour). The biological system setup, in both cases, has been upgraded to accommodate BPC Sequential Mode Bioremediation (illustration shown above)

Attention: BPC sample & Control system includes TOC analyzer (COD analyzers are less accurate) so we use a factor for each site to transform TOC to COD

Note: TOC Degradation statistics were taken from BPC BI system

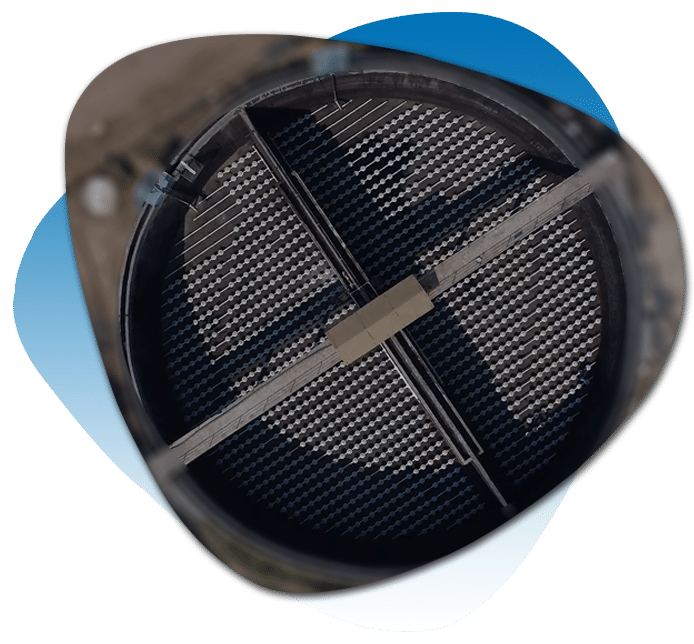

WORKING OF

ACT Technology

- A bacteria batch is isolated from the effluent.

- This bacteria culture is maintained in an Auto-Starter Basin (batch reactor which is 10% of the main bioreactors volume) near the bioreactor in case the system needs to be shutdown (e.g. for maintenance), the culture is always ready to repopulate the bioreactor, and the bacteria culture is the proprietary information of the client (in this case IOCL Panipat Refinery)

- A control system monitors parameters like TOC(Total Organic Carbon), TN(Total Nitrogen), TP(Total Phosphorus), pH, DO(Dissolved Oxygen), OUR(Oxygen Uptake Rate), and based on these parameters runs the system automatically, ensuring smooth operations and instantaneous reaction to inlet parameters.

ACT PROJECTS IN

INDIA

- IOCL PTA ETP - Panipat, Haryana

- OPAL Petrochemical Complex Installation (Operational since 2016- EIL managed Tender) - Dahej, Gujarat

- BPCL Refinery, ETP under Integrated Refinery Extension project - Kochi, Kerala

- Naroda Enviro Projects Limited CETP - Naroda, Gujarat

- HMEL Refinery - Bhatinda, Punjab

Testimonials

What Our Client’s Say

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

Design is a way of life, a point of view. It involves the whole complex of visual commun ications: talent, creative ability, manual skill, and technical knowledge.

contact us

Book your free consultation

Got any questions regarding our technology ?

Let us know, we will be glad to assist!!!