COMPANY OVERVIEW

BioPetroClean™

Delivering Ecological Solutions for Industrial Wastewater

BioPetroClean™ is a cleantech company specializing in biological wastewater treatment.

Solutions based on our proprietary bioremediation technology named ACT (Automated Chemostat Treatment) which has innovative processes that enable and guarantee major improvements in any wastewater treatment (WWT) plants.

Our advanced wastewater treatment system has been field-proven and has been shown decrease contamination to levels lower than government discharge standards. The output is virtually sludge-free and the recycled wastewater can be returned to its natural source.

ACT RETROFIT ™

Automated Chemostat Treatment ™

ACT technology is valuable for plants seeking solutions for absorbing high “Inlet load”, OPEX reduction, treating difficult streams containing high Phenols, Ammonia, Cyanides, High TDS and high fluctuating inlet contaminates. ACT can be applied to a wide variety of sites including oil refineries, terminals, drilling sites, marine ports, power stations, contaminated reservoirs, and storage tanks.

Reducing sludge production (reducing operating costs)

Reducing plant upsets (improving plant reliability)

Reducing load on equipment downstream from the bioreactor (increasing current plant capacity)

Solutions we offer

Our solutions & services are tailored to meet each plant demands and include complete process automations as “Add-on“

Complete WWTP

Turnkey Delivery

We are a complete waste water management company with engineering capabilities to undertake & execute turnkey solution for waste water treatment solutions.

WWTP

Upgrade/Retrofit

BPC has developed a novel technology for treating wastewater that prevails over the limitations of existing and conventional technologies called Automated Chemostat Treatment™ (ACT).

Site Study &

Lab Study

Our detailed Site & Lab Study enables us to give a guaranteed tailor-made solution specific to the site and client requirements. Solutions are based on real time sample collection from plant.

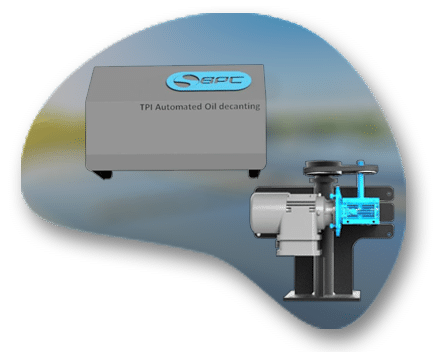

TPI Automatic

Oil Release

Revolutionizing the age old TPI unit by adding the BPC Oil Detection and Auto Oil Release System which eliminates operator dependence of Oil Removal and enables the unit to give best performance all the time.

Automated

Chemical Dosing

Intelligent Chemical Dosing systems are based on inputs from Process Experts, through application of embedded analytics the system is able to adjust the Chemical Dosing Rates in Real-Time, & operational in ETP’s successfully.

Professional

O&M Services

BPC offers a range of complimentary services. BPC also offers its professional supervising services to WWT plants who did not acquire ACT yet allowing them to benefit from BPC expertise to improve their WWTP performance.

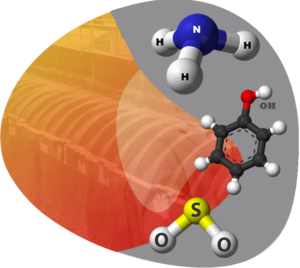

Sulfides

Oxidation

Sulphide removal is one of the biggest challenge for refinery Effluent treatment. It requires usage of expensive chemicals like H2O2 which pose handling difficulties as well.

Ammonia

Nitrification

While most of the aerobic systems are unable to treat ammonia in the effluent, BPC ACT system is immune to high ammonia (50-500 ppm) concentration but also can treat ammonia without any extra infrastructure .

Phenol

Bioremediation

Bioremediation process is one of the cost effective process to treat biological contaminants like COD, BOD etc. The process gets affected with increase in other inorganic contaminants.

Problematic Streams

Sulfides Oxidation

Ammonia Nitrification

While most of the aerobic systems are unable to treat ammonia in the effluent, BPC ACT system is immune to high ammonia (50-500 ppm) concentration but also can treat ammonia without any extra infrastructure .

Phenol Bioremediation

Bioremediation process is one of the cost effective process to treat biological contaminants like COD, BOD etc. The process gets affected with increase in other inorganic contaminants.

Project Idea

Business Conception

Legal Rewiew

Infrastucture Design

Company Established

Our Team

Meet our Professionals

We have more than 15 years experience backed up by a can-do attitude delivering high-end, & effective wastewater solutions on time and budget.

Our Network

Industries we serve

Cum et essent similique. Inani propriae menandri sed in. Pericula expetendis has no, quo populo forensibus contentiones et, nibh error in per. Vis in tritani debitis delicatissimi, error omnesque invenire usu ex, qui illud nonumes ad.

Cum et essent similique. Inani propriae menandri sed in. Pericula expetendis has no, quo populo forensibus contentiones et, nibh error in per. Vis in tritani debitis delicatissimi, error omnesque invenire usu ex, qui illud nonumes ad.