Introduction

BioPetroClean has successfully completed a project for produced water treatment. One of India’s governmental companies for oil excavation and production was searching for a wastewater purification process that will allow re-injection of produced water and will also be cost- effective and easily operated. The BPC- ACT treatment was straightforward and simple, resulting in a significantly lower sludge level, which allowed a more effective and economical post-treatment and disinfection of the produced water.

Produced water, also known as drilling water, is wastewater created by the process of petroleum extraction from underground reservoirs. Large quantities of high pressure, very hot water are pumped into the petroleum reservoir during the mining process. The water pressure forces the petroleum upward, while the heat lowers its viscosity. After this water is cooled and as much of the oil is extracted, the remaining wastewater requires cleaning to eliminate all of the additional oils and other organic and inorganic compounds. The annual volume of produced water is currently estimated at 77 billion barrels (bbl) and is expected to grow exponentially in the coming years. These high quantities represent the overwhelming majority of the volume of waste streams produced by the oil and gas industry.

BPC’s innovative, efficient and cost – effective technology is a potent solution for produced water purification. Prior to implementing BPC’s suggested solution, the client utilized a heater- treater followed by a simple chemical treatment.

Figure 1: BPC installation for purification of produced water

BPC’s Technology

BPC’s cutting-edge biological method for wastewater treatment offers an elegant and simple solution to overcome the existing challenges of conventional biological methods. The method, known as Automated Chemostat Treatment™ (ACT), is based on maintaining a pre- selected bacterial “cocktail” tailored for the wastewater type at a stable and low concentration while monitoring the system with a fully automated control unit. The control unit measures the various parameters of the influent, including COD, TPH, salinity, turbidity and pH, among others. The control unit is able to adjust the conditions in the bioreactor in order to maintain a stable output and prevent system upsets.

BPC’s Solution to client’s need

The BPC solution in this project involved three stages. First, a feasibility study and extensive analyses of wastewater samples from the client’s site were performed at BPC’s laboratory. Next, based on the lab results, BPC designed and implemented a pilot system that included a BPC-ACT bioreactor and a cascade of post-treatments. Finally, based on the on-site experience, BPC was able to design a full-scale process, which was submitted to the client for approval.

Preliminary Lab Analysis

BPC received samples of the client’s wastewater and analyzed them extensively in order to develop an optimal biodegradation process. Following basic characterization of the water (which included measurements of the carbon and nitrogen load, as well as the pH and salinity and other parameters), the water underwent several stages of biological treatments. These cycles allowed for optimization the bacterial cocktail that was later used for the pilot experiment. The preliminary water characterization and the biological treatment performed in BPC’s labs are presented in the table below.

| BPC Preliminary Lab Results | ||

|---|---|---|

| Parameters | Before Treatment | After Treatment |

| TPH (ppm) | 16.2 - 247 | 1 to 3 |

| COD (ppm) | 646 - 2493 | 100 to 200 |

| TOC (ppm) | 97 - 406 | 30 to 50 |

| Phosphate | 0.6 - 4.4 | --- |

| pH | 8 - 8.4 | 8 - 8.4 |

| Salinity (%) | 0.79 - 0.92 | 0.79 - 0.92 |

| Conductivity (mS) | 15 | 15 |

| Sulfate (ppm) | 22 - 140 | --- |

| Sulfide (ppm) | 0.48 - 1.37 | --- |

| Ammonium (ppm) | 13.9 - 8.0 | 3 to 6 |

| Turbidity | 41 - 361 | 6 to 12 |

| TSS | 17 - 161 | 8 to 14 |

Pilot Configuration and Implementation

After completing the lab analysis and demonstrating the viability of ACT as an effective bioremediation solution, BPC proceeded with an on-site pilot project. The pilot system included the BPC-ACT™ bioreactor, followed by a clarifier, ultrafiltration and de-contamination with biocides for fine-tuning of the water quality. The pilot system operated for a period of eight weeks. The system was dedicated to the treatment of produced water sourced from the client’s regional oil production sites. Produced water underwent biological treatment in the BPC-ACT bioreactor using the pre- selected bacterial cocktail. Following the bioremediation process, the treated water was sent first to a mixer then a clarifier. The upper phase then underwent ultrafiltration and was finally treated with biocides in order to eliminate any traces of sulfate reducing bacteria (SRB).

Pilot Results

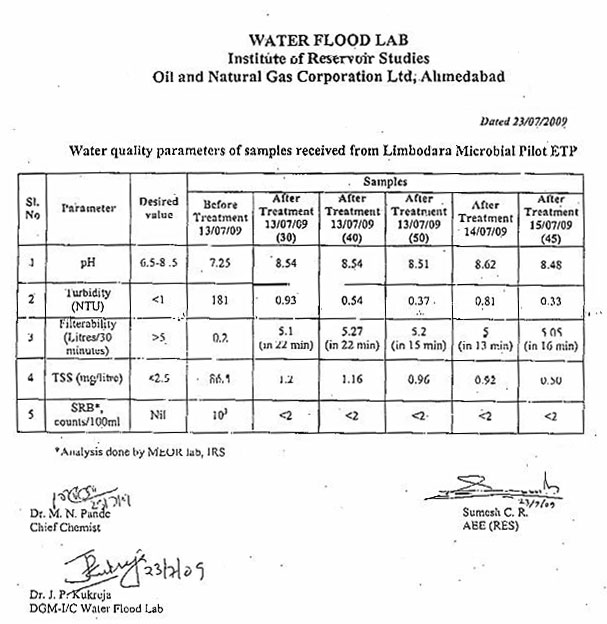

During the pilot trials, the water was sampled and analysed by both BPC staff and the local Institute of Reservoir Studies (IRS). As shown in the table below, the BPC treatment process resulted with very satisfying results. It is indicated in the table provided by the IRS that the turbidity was reduced from 181 NTU to 0.33-0.93 NTU, while the desired value was <1 NTU. Similarly the TSS levels exceeded the desired values with less than 2.5 ppm in the end of the treatment process. The SRB levels were negligible, as required and the filterability of the water was high. Throughout the pilot, the pH was in the range of 6.5-8.5, as expected.

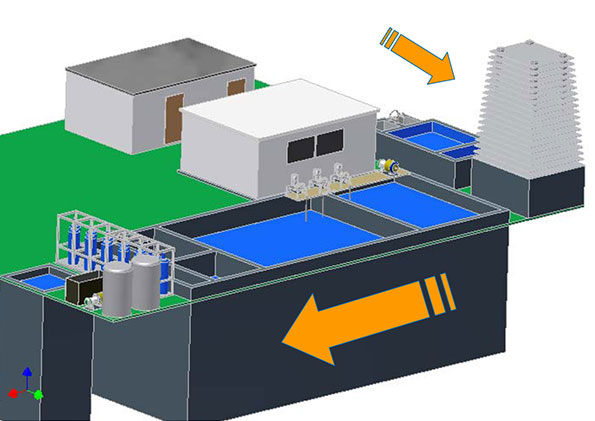

The Next Step Permanent System

Following completion of this successful pilot, the client was very pleased with the system’s performance. The combination of the BPC-ACT bioreactor along with a series of post-treatments yielded highly purified water that could later be re- injected into the oil well. The experience that BPC has gained by performing the pilot at the actual drilling site allowed us to design a full-scale system that is most suitable to the field conditions as well as the client’s needs. The permanent system is expected to work in a continuous mode and include a cooling tower followed by two consecutive bioreactors with a total residence time of approximately 40 hours. The bioreactors will be continuously monitored by the BPC-ACTTM control unit in order to maintain a steady state inside the bioreactors and allow a stable process. The biologically treated water will be filtered and treated with biocides prior to its re-injection.

Figure 2 : BPC layout of the full scale installation

The Valuable Contribution of BPC

BPC’s solution for treating the produced water is highly advantageous for the following reasons:

- High efficiency – The BPC-ACT treatment of produced water can bring highly contaminated water to a purity level that allows for its re-injection. The treatment process is completed with a relatively short retention

- Cost savings – Resulting with extremely low biomass levels, BPC- ACT significantly reduces the amount of biocides required prior to re-injection and also reduces the ultrafilters wear over

- Simple construction – The process infrastructure is mainly based on currently available infrastructure, thus considerably reducing the time and costs required for the system’s installation.

- Simple operation – The system is completely automated, leading to a simple and straightforward operation and eliminating the need for highly skilled operators.

Summary

BPC offers a simple and efficient solution for purification of produced water to a level that will allow its re-injection into the oil-well. An on-site pilot in a drilling water gathering station in India resulted with TSS, turbidity, filterability and SRB levels that exceeded the client’s requirements. Based on the information gathered during the pilot, BPC has performed a preliminary plan for a full- scale system. The on-site treatment demonstrated that implementing the BPC-ACT technology leads to highly purified water in a simple and cost effective way.

Optimization Statistics

From the designers and engineers who are creating the next generation of web and mobile experiences, to anyone putting a website together for the first time. We provide elegant solutions that set new standards for online publishing.

Digital technology has made our world more transparent and interconnected, posing new challenges and opportunities for every business. A holistic, user-centric perspective is what truly sets one apart. together for the first time. We provide elegant solutions.

From the designers and engineers who are creating the next generation of web and mobile experiences, to anyone putting a website together for the first time. We provide elegant solutions that set new standards for online publishing.

We Will Be Useful to You

From the designers and engineers who are creating the next generation of web and mobile experiences, to anyone putting a website together for the first time.

Digital technology has made our world more transparent and interconnected, posing new challenges and opportunities for every business. As your budget progresses and evolves, continue referring to your SMART objectives. Stay focused and remember your goals – they will always inform what your next step will be!

From the designers and engineers who are creating the next generation of web and mobile experiences, to anyone putting a website together for the first time. We provide elegant solutions that set new standards for online publishing.

As your budget progresses and evolves, continue referring to your SMART objectives. Stay focused and remember your goals – they will always inform what your next step will be!