Introduction

Bio Petro Clean successfully completed a retrofit upgrade project for Naroda Enviro Projects Limited for their Common Effluent Treatment Plant. One of India’s CETP was searching for a solution for their Treatment process in order to enable SUSTAINABLE HIGH QUALITY OUTPUT.

The target set was to achieve consistent compliance and output quality as per the Pollution Board norms.

CETP receives nearly 9.6MLD effluent, segregated further in four streams viz. chemical, sewage, food and textile. NEPL required a solution that would treat water and discharge in an easy and cost-effective manner to the nearby river.

Issues/ Challenges NEPL management was facing:

- COD levels were not met at the outlet stream: CETP has a very high fluctuation of COD at the inlet, especially for the chemical and pharma streams. The poor treatment process was not able to treat the effluent as per required norms of GPCB. The COD was much higher than the required outlet values.

- TSS levels were not met at the outlet stream: The different kind of streams in the inlet of CETP requires a very technical and full proof plan for treatment .Despite of having a very good settling system the TSS at the outlet was very high. The main reason was poor treatment in biological system.

- Turbidity levels were not met at the outlet stream: The high tss was contributing to high turbidity at the outlet. This unsettling suspension of solids needed a better biological process with a good clarification system.

- Poor performance of the CETP during invariable shock loading of the inlet flow: Despite of a sufficient infrastructure the biological process was very poor and unable to handle the shock loads of the inlet. The CETP needed a better and stable biological process to take in the shock loads without compromising the outlet values .

- ASP MLSS was not maintained as per requirement of the process: The CETP had anaerobic and ASP system to treat the streams. However due to the variable shock loads and nature of effluent the aerobic system was not able to sustain a good MLSS. The poor MLSS was not giving optimum performance and hence poor outlet.

- Variable inlet contaminants: The CETP has at least 200 factories of Dyes and textiles which send their effluent to the CETP for treatment. Apart from different kinds of streams like Pharma, sewage, textiles, food and chemical the streams themselves has a big variety of effluent type. The effluent composition changes with the change of manufacturing of product in the factory. This was biggest challenge for the treatment.

Implementation of BPC- ACT Technology

Following is a comparative analysis given for the Pre-BPC and after BPC ACT implementation in the CETP in operation. The plant is being operated by BPC personnel and with the cutting edge technology that our Software Pure – Business Intelligence provides; it became easier to maintain the plant at optimum level w.r.t to the sustainability.

| Pre BPC | After BPC | Proposed/ under process treatment | |||

Parameters | Inlet | Outlet | Inlet | Outlet | Inlet | Outlet |

COD (ppm) | 4900 | 2000 – 3000 | 4000 | 400 | 4000 | <250 |

OUT TOC (ppm) | – | – | 1200 | <150 | 1200 | <85 |

DO (ppm) | 0.12 | – | – | 2+ | – | 2+ |

pH | 8.27 | 8.2 | 8.27 | 7.3 | 8.25 | 7 |

TSS (ppm) | 1500 | 1500 | 1500 | 75 | 1500 | <75 |

Turbidity (NTU) | – | – | – | 38-40 | – | <40 |

The Challenge

The streams that are entering the CETPs are from various sources, so it was very hard to get the estimate of effluent entering the plant. Moreover, the effluent entering the system was difficult to biodegrade; hence to meet the outlet norms as per the pollution board was a challenging task. The optimization of plant as proposed was achieved in different stages.

- 1st Stage– Getting COD below 500 ppm and rest of the parameters under limits

- 2nd Stage– Cost Optimization

- 3rd Stage– Reducing the COD to below 250 ppm (Under Implementation)

- 4th Stage– Cost Optimization.

Once all the stages are complete, the Outlet will be stable with all the parameters meeting at outlet and at Optimum conditions.

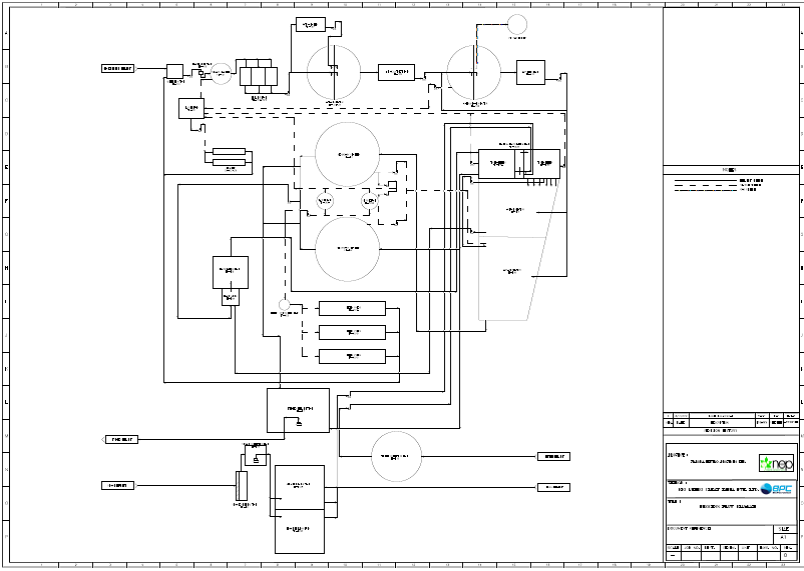

PFD Scheme after implementation of BPC-ACT Technology

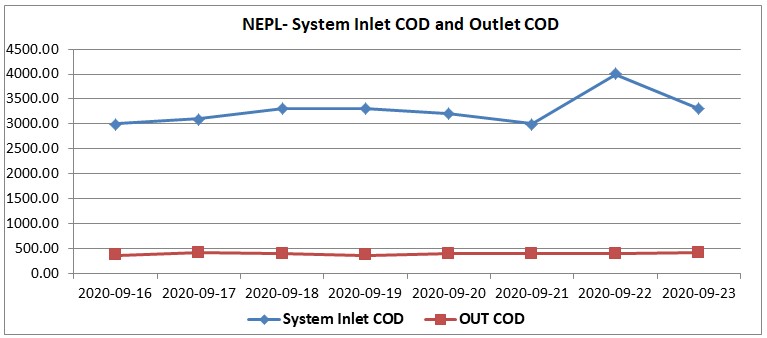

The Outlet parameters after the installation for ACT were determined as below

(Note : All units in ppm)

| Category | COD Deg In % | System inlet TOC | System Inlet COD | System Flow (m3/hr) | Out TOC | OUT COD | Out Turbidity (NTU) | Out TSS |

| 2020-09-16 | 88.00 | 1059.67 | 3000.00 | 223.33 | 118.67 | 360.00 | 38.59 | 100.00 |

| 2020-09-17 | 86.45 | 1132.67 | 3100.00 | 233.33 | 117.33 | 420.00 | 47.49 | 96.67 |

| 2020-09-18 | 87.88 | 989.00 | 3300.00 | 240.00 | 128.00 | 400.00 | 59.49 | 80.00 |

| 2020-09-19 | 89.09 | 959.00 | 3300.00 | 240.00 | 123.67 | 360.00 | 75.71 | 70.00 |

| 2020-09-20 | 87.50 | 1014.50 | 3200.00 | 240.00 | 120.00 | 400.00 | 60.27 | 70.00 |

| 2020-09-21 | 86.67 | 983.50 | 3000.00 | 245.00 | 117.50 | 400.00 | 37.02 | 75.00 |

| 2020-09-22 | 90.00 | 1155.00 | 4000.00 | 250.00 | 121.50 | 400.00 | 45.81 | 75.00 |

| 2020-09-23 | 87.27 | 1125.33 | 3300.00 | 256.67 | 117.33 | 420.00 | 48.94 | 100.00 |

1. System Inlet and Outlet COD:

The COD levels at the outlet stream were well within the GPCB norms, and the results were validated by the Pollution board itself (note: the results were validated on 22nd Sept 2020)

| Outlet COD | |

| Max | 420.00 |

| Min | 360.00 |

| Average | 395.00 |

| St. Dev. | 23.30 |

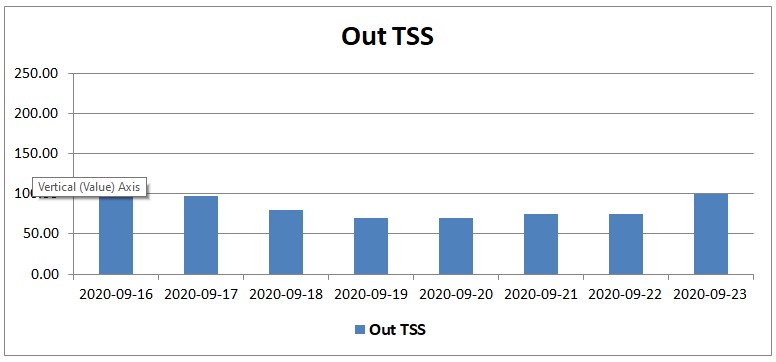

2. System Outlet TSS (before BPC-ACT TSS levels ~ 1500 ppm)

| Outlet TSS | |

| Max | 100.00 |

| Min | 70.00 |

| Average | 83.33 |

| St. Dev. | 13.30 |

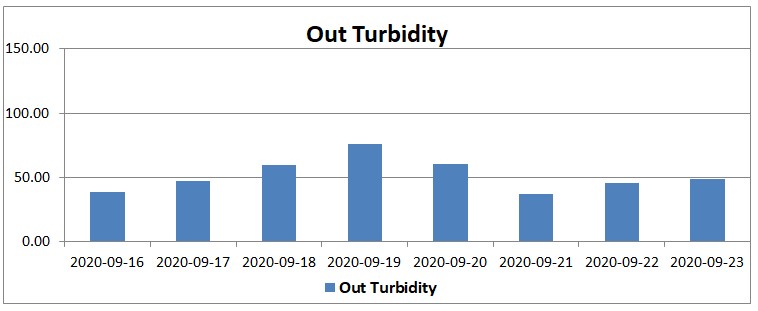

3. Outlet Turbidity Levels

| Outlet Turbidity | |

| Max | 75.71 |

| Min | 37.02 |

| Average | 51.66 |

| St. Dev. | 12.86 |

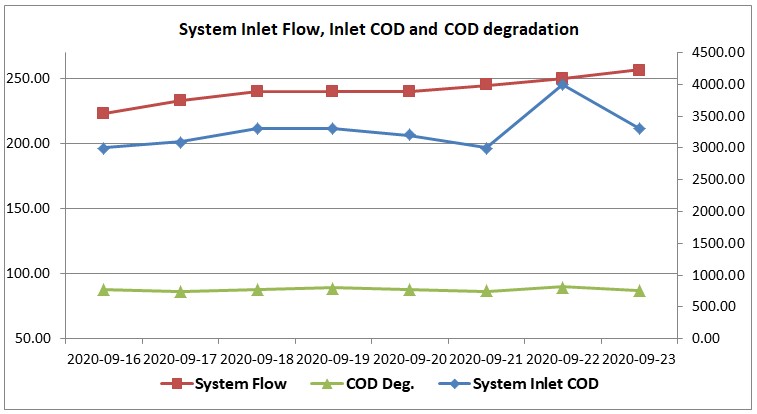

4. System Inlet flow, Inlet COD and COD degradation in the System

During the inlet shock loads with respect to the invariable flow-rate the CETP was not performing to satisfactory levels, hence NEPL management was looking for a solution which will give sustainable output results during the invariable low and high capacities of inlet flow rate.

After BPC- ACT implementation: It can be clearly noted in the graph represented below that the COD degradation is very good In spite of increase in feed flow as well as fluctuation in inlet COD.

Average Inlet COD of Each Stream

The Average Inlet COD (in ppm) of both the streams are mentioned below for month wise category. There are fluctuations in Inlet streams and according to the COD at inlet and Flow the Chemicals are used.

SFT: Sewage; Food; Textile streams

| Average COD of streams at inlet (ppm) | |||||||||

| April | June | July | August | September | |||||

| Chemical Stream | SFT Stream | Chemical Stream | SFT Stream | Chemical Stream | SFT Stream | Chemical Stream | SFT Stream | Chemical Stream | SFT Stream |

| 2830 | 380 | 3800 | 720 | 3100 | 650 | 3740 | 640 | 3590 | 660 |

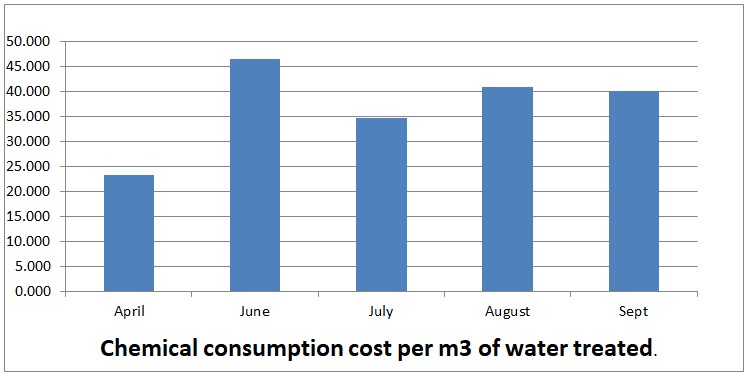

5. Chemical Cost per m3 of Treated Water

Below, the treatment cost of water for per m3 of effluent processed w.r.t. the chemical consumption is given. The Cost is calculated as the TOTAL CHEMICAL CONSUMPTION COST/ TOTAL WATER TREATED in m3.

| Chemical cost per m3 of water treated (INR) | |

| April | 23.224 |

| June | 46.491 |

| July | 34.744 |

| August | 40.843 |

| Sept | 40.107 |

The Results obtained from this graph is based only on the amount of water processed by the CETP. Now, for Calculating the Actual cost of treatment (COD basis), we have to Consider the inlet COD of the system. For this we will take Inlet COD Load of the system.

- Inlet COD load= (inlet COD*Total flow)/1000

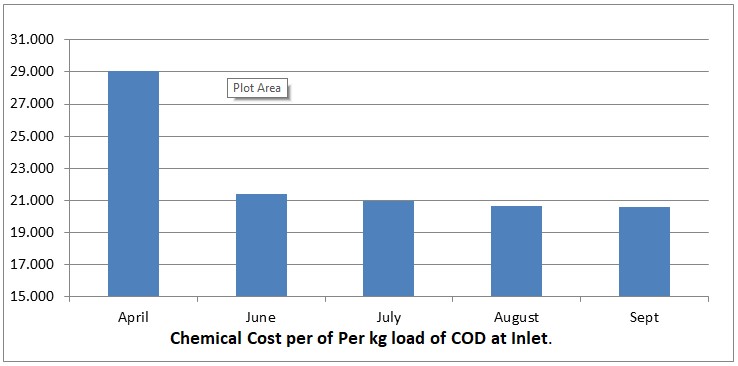

6. Cost of per kg load of COD at inlet

Below, the treatment cost of chemical consumption per kg of COD load at inlet is calculated,

| Chemical cost per kg load of inlet COD (INR) | |

| April | 29.055 |

| June | 21.368 |

| July | 20.952 |

| August | 20.669 |

| Sept | 20.584 |

The Chemical cost consumption per kg of COD load at inlet for the CETP is decreasing every month. This shows the efficiency and savings in the OPEX.

Summary

BPC offered a simple and efficient solution for upgrading old effluent treatment systems to a level that will allow for safe discharge of treated wastewater. BPC not only implemented ACT there but also streamline the process and parameters for the plant and are maintaining the outlet and meeting every guideline set up by the environmental Agencies. Also substantial savings can be obtained on the Opex terms.

The toughest challenge to variable products and the effluent produced from the manufacturing. Handling a COD variation is much easier but when it comes to handling different contaminants in the effluent is a very challenging task.

ACT is a breakthrough for such effluents as the bacteria is isolated and grown as per the effluent. So, BPCs ACT system is successfully running on this site with the tailored bacteria handling all kinds of variations without compromising the outlet quality.

The BPC-ACT solution can easily be integrated into currently existing infrastructure, resulting in a more cost effective and environmentally friendly wastewater treatment. The retrofit process is quick and relatively painless, and leads to a superior a more stable means of effluent treatment.

Optimization Statistics

From the designers and engineers who are creating the next generation of web and mobile experiences, to anyone putting a website together for the first time. We provide elegant solutions that set new standards for online publishing.

Digital technology has made our world more transparent and interconnected, posing new challenges and opportunities for every business. A holistic, user-centric perspective is what truly sets one apart. together for the first time. We provide elegant solutions.

From the designers and engineers who are creating the next generation of web and mobile experiences, to anyone putting a website together for the first time. We provide elegant solutions that set new standards for online publishing.

We Will Be Useful to You

From the designers and engineers who are creating the next generation of web and mobile experiences, to anyone putting a website together for the first time.

Digital technology has made our world more transparent and interconnected, posing new challenges and opportunities for every business. As your budget progresses and evolves, continue referring to your SMART objectives. Stay focused and remember your goals – they will always inform what your next step will be!

From the designers and engineers who are creating the next generation of web and mobile experiences, to anyone putting a website together for the first time. We provide elegant solutions that set new standards for online publishing.

As your budget progresses and evolves, continue referring to your SMART objectives. Stay focused and remember your goals – they will always inform what your next step will be!